| -->down <--about me | | [1] | [2] | [3] | page 4 of 7 | [5] | [6] | [7] |

THE Goldhofer AST-1 X is growing (Part 1)

The building of the biggest towbarless aircraft tractor of the

world

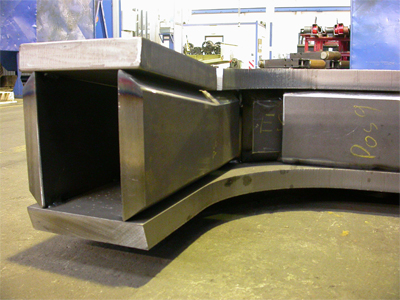

[1] - May 2004: Parts of the mainframe prepared for welding... |

|

|

In May 2004 the first plates are prepared for welding to form one of the main beams. For the main frame high tensive steel plates are used up to 6 in / 150 mm thickness. |

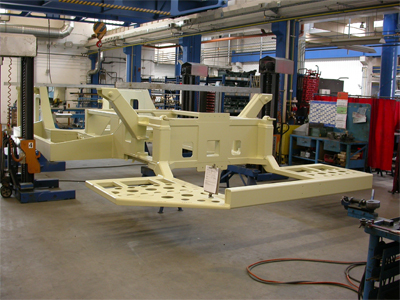

[2] - June 2004: The mainframe is finished... |

|

|

The welding of the main frame for the first

AST-1 X prototype was finish by end of June 2004. In total we used about 30.000 lbs / 15.000 kg steel plates of best quality and also some special steel profiles for the main frame of the tractor. The AST-1 X is designed for a max. nose landing gear load of 135.000 lbs / 60.000 kg (compareable with the fifth wheel load of an articulated truck) and for a max. aircraft weight up to 1.320.000 lbs / 600.000 kg. |

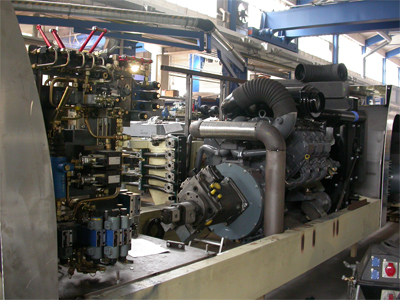

[3] - August 2004: The two diesel engines are mounted... |

|

|

The first prototype is equipped with two

Deutz (KHD) V6-cylinder Diesel engines type BF6M1015 C. The total power

of 2x 400 HP = 800 HP is distributed by hydraulic oil to the hydraulic

motors, each in one of the 6 driven wheels (6x6). In the biggest version the AST-1 X can be equipped with two Deutz (KHD) V8-cylinder Diesel engines type BF8M1015 CP, each rated at 600 HP. With this 1.200 HP hydrostatic drive system the tractor is able to reach the max. speed of 20 mph / 32 kph also with an aircraft weight of 600.000 lbs / 300.000 kg! |

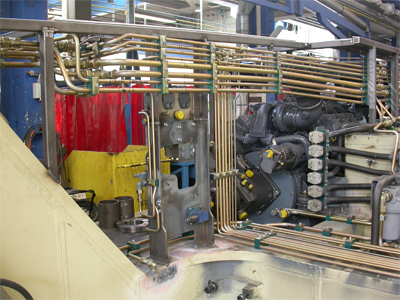

[4] - October 2004: The piping is finished... |

|

|

To get the power of 2x 400 HP Diesel engines

to the wheels and to serve the hydraulic systems for steering and the

pickup-system we installed more than 1.000 meter (more than 3.000 ft) of

steel pipes. The hydraulic oil tank has a capacity of about 600 litres and while driving with max. power up to 1.500 litre per minute oil flow is going through all of the 6 hydraulic motors in the wheel gears. Keep in mind: a power rating of more than 200 HP is going to each wheel! |

[5] - November 2004: the pick-up-system for the nose landing gear is mounted... |

|

|

The pickup-system, which is designed to

clamp the tires of the nose landing gear to lift the aircraft, is

completed and mounted within the vehicles main frame. We use the original size of the A380 nose gear tires for testing. |

[6] - December 2004: the new designed cabin is mounted... |

|

|

In December 2004 the completely new designed

cabin is mounted on a lifting device at the tractors front end. To allow best visibility for the driver not only the cabin can be lifted by hydraulic up to 22 in / 550 mm - the steering wheel with all instruments is mounted on a turntable, which can swivel with 180 degree to get best visibility for the driver to the nose landing gear while picking up the aircraft. |

| <--up <--about me | | [1] | [2] | [3] | page 4 of 7 | [5] | [6] | [7] |